In his last Exhibition World blog, managing director of Leach Impact Richard Leach (pictured, main) highlighted the common failings of fabric graphics. In this latest instalment he shares the secret to maximising ROI from this event stand solution…

As with many areas of business, risks can arise in many guises. However, if they are understood and prevented before a project even begins, the assignment can actually be extremely straightforward.

Transfer this mindset to the world of fabric graphics and the same ethos applies. If an exhibition stand builder understands the reasons why 1 in 2 such graphic installations fail, the potential pitfalls can be avoided, crowd pleasers can be achieved every time and ROI can be maximised as a result.

So how exactly can a contractor overcome these pitfalls?

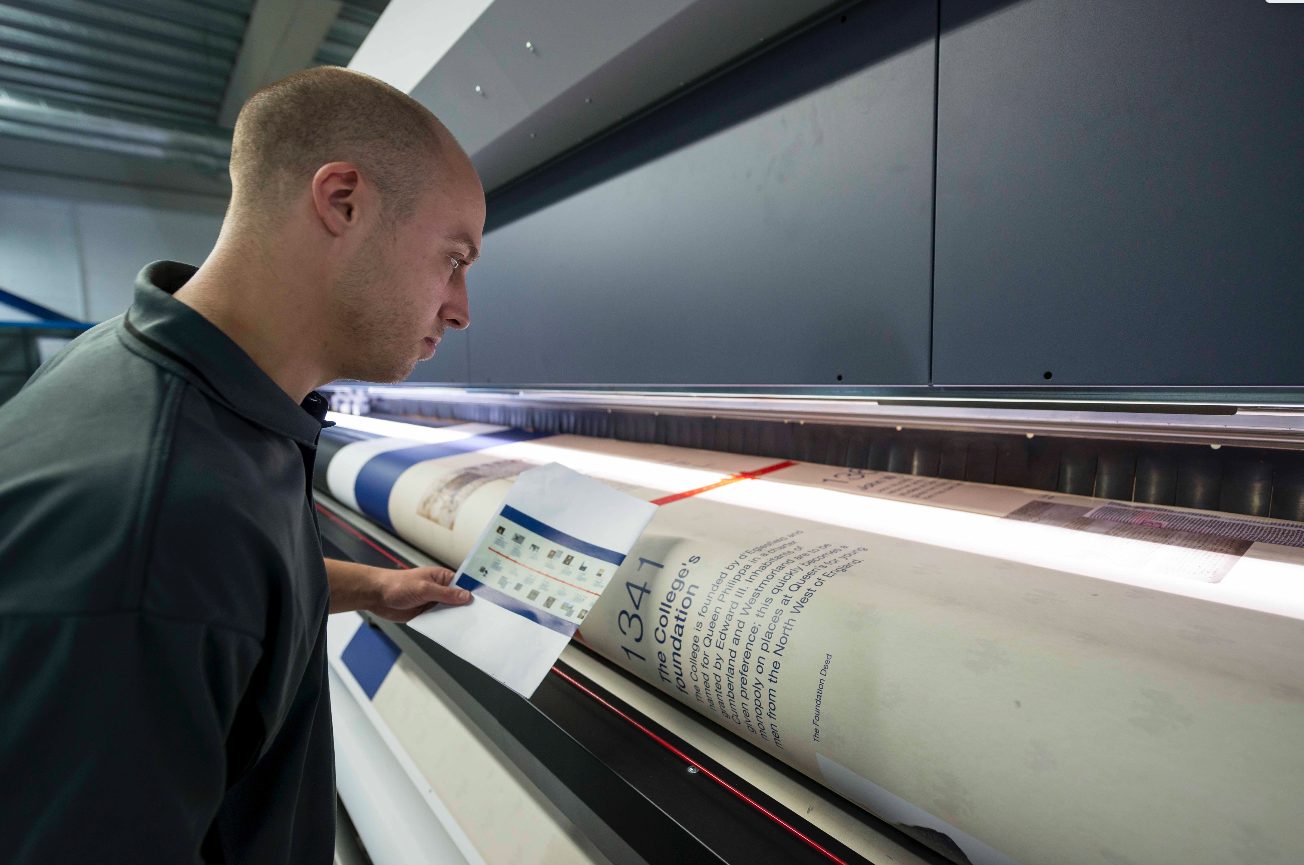

In truth, beyond an accurate graphics specification, much comes down to the quality of the appointed supplier. A vast degree of knowledge is required to produce high quality, large-format stretch fabrics which are right first time – this is certainly not an area that wide-format banner printers can simply experiment in.

In the hunt for a perfect partner, stand builders should therefore look for:

- A supplier that understands sizing for frame systems

There are many factors the print producer needs to take into account to ensure the perfect fit, which can cause considerable confusion:

- An allowance needs to be made for the graphic to stretch, so that it is held under the correct tension in the frame and therefore stays flat and crisp. This will be different for each fabric type due to differential degrees of stretch.

- Another allowance should be also made for fabric shrinkage during the print finishing process (if a dye sublimation print process is used). Again, this can be different for each fabric type.

- A final size adjustment should account for the amount of bleed required to hold the silicone edging strip, which folds into the frame.

These points illustrate how vital it is that the printer and stand builder talk the same language when it comes to specifying sizes.

- A partner that knows its inks

Fabric graphics are almost exclusively produced using either dye sublimation or UV curing inks. In the case of the latter, it is of critical importance that the correct ink type is specified – a dedicated fabric ink with built-in flexibility is essential to resist cracking when folded, or flaking when held under tension in the frame.

Modern large-format printing machines are not designed for frequent ink type changes, and dedicated fabric inks are more expensive than conventional ones. So, a print producer that does not specialise in fabric graphic production is unlikely to use the ink that they should.

- A partner that understands the characteristics of the fabric

Different applications demand different fabric types to create the dramatic impact that exhibitors require. Curved and flat applications need fabrics with different stretch characteristics for optimum effect, for example, whilst backlit, front-lit and block-out applications all require the correct fabric to be chosen to avoid disappointment.

All in all, the print provider needs to have a full range of suitable fabrics at their disposal, and must understand the stretch and colour profiling characteristics of each material to ensure the finished result gives the maximum impact.

- A partner that always uses machine cut techniques

Super large-format fabric graphics require an equally large cutting table. In the absence of this, the supplier may revert to less accurate hand-cutting techniques which are fraught with danger.

For instance, it is difficult to accurately measure and hand-cut a large graphic to the required tolerance levels of 1 or 2mm, and true 90 degree corners are difficult to achieve. This means that, even if the fabrics are measured to the correct size, the graphic will still not fit the frame if not entirely right-angular.

- A partner that understands colour profiling

Brands and exhibitors quite rightly demand strong and accurate colour reproduction of their artwork. However, fabric substrates do not have the same ink-receptive properties as paper or most other commonly used large-format print media. The supplier must therefore apply dedicated colour profiles for high quality reproduction onto fabric materials, which requires a calibrated spectro-photometer and profiling software.

When the fabric is going to be rear illuminated, a totally different colour profile should be chosen because the light behind the graphic can ‘bleach’ out the colours and reduce the apparent saturation. This effect is particularly visible in weak blacks, low contrast images and pale Pantone shades.

A great degree of technical knowledge is required to produce fabric graphics of the necessary quality, but find the right partner – for which this specialist arena is the norm – and the benefits of installing this type of exhibition stand solution will far outweigh any risks.

Richard Leach is managing director of Leach Impact, a graphic display specialist with a 125 year heritage.